The Tuff Wheelchair

Design Internship Project

March 2021 - August 2021

Studio 930 Design Consultancy

Rochester Institute of Technology

About the Project

Children who are disabled in the country of Rwanda have to travel for long distances on unpaved roads to attend school. Most of these children have to overcome a lot of obstacles such as muddy, sandy and rough terrain as they travel through the Rwandan countryside.

Schools in Rwanda are often miles away from children’s homes. Without a proper transportation method, children who use wheelchairs can be further isolated from their peers when they are unable to attend school due to travel limitations.

Initial Observations

Rwanda is a hilly country

Roads in rural Rwanda is not well laid

School children have to travel long distances to attend school

Research

Researched on

-

Materials that are readily available

-

Materials that are inexpensive

-

Parts that can be easily repaired

-

Components that can be easily used to assemble a wheelchair

-

Researched about the terrain of Rwanda

-

Explored wheelchair configurations

-

Researched ways on making a simple drive mechanism for forward motion.

-

Gathered data on wheelchair standards and dimensioning

-

Researched about the climate and the terrain of Rwanda

Key Findings

Rwanda has two rainy seasons: March to May and September to November. Rural roads become muddy during rainy weather. Wheelchair design uses easily replaceable parts and recycled bicycle materials, with a ball bearing drive mechanism for rough terrain.

User Reseach

John

-

8 years old

-

Lives in Rural Kigali

-

School Student

-

Suffers from Moderate Cerebral Palsy

John is a school going student at the local school outside of the Rwandan Capital of Kigali. He has been suffering from Moderate Cerebral Palsy (which is a disorder in the nervous system which causes muscle and motor disorders) since he was 4 years old.

Ever since then, his parents would ask local bicycle repair shops to build a custom-made wheelchair out of old used bicycle parts which used to get the job done such as travelling to school etc.

His custom-made wheelchair is just a workaround because most of the wheelchairs that are designed to withstand hard and rough terrain are simply very expensive for his family to afford. He is accompanied by his friends or sometimes his parents when he goes to school. Most of the time his friends push him on his wheelchair taking turns when they accompany him to school.

Areas to Focus

Low cost and functionality of the final design

Understanding on how the design can be manufactured using resources available locally

Exploring chassis and wheel configurations for wheelchair that will help tackle rough terrain

Anthropometric Analysis

Key Conclusions and Decisions made

-

The larger wheels on the front of the wheelchair will help better tackle rougher terrain better (large rocks, stony paths etc.) than having the caster wheels in the front.

-

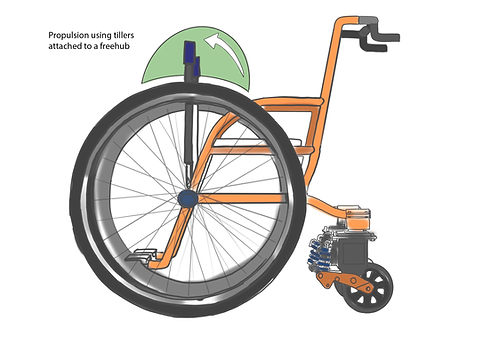

Having a tiller/lever directly attached to the larger front wheels via a bearing drive will help in maneuver over curbs and rocks easily. It will also facilitate a faster way to travel long distances.

-

Having a larger set of front wheels may not be ideal but will help the user in getting less tired as the tillers will make it easy for them to be more mobile.

Inspiration

The GRIT Freedom chair designed and developed by MIT

A wheelchair attachment made out of 3D printed parts designed and developed by Kate Reed

Wheelchairs used in sports such as wheelchair rugby and wheelchair basketball

Wheelchairs designed and developed to handle rough terrain with larger front wheels

Ideation

Prototype

.jpg)

Proof of Concept

Prototype

Materials used in making the prototype

-

Zinc Plated Punched square tubes.

-

Nuts and Bolts

-

Two 26 inch bicycle wheels

-

Two 16 inch wheels

-

Two levers

-

Two ball bearing drives

Testing Outcomes

-

The proof-of-concept prototype was just a bare bone prototype to demonstrate the mechanisms and the overall working

-

During testing, the prototype was tested to see if the large front wheels can overcome curbs of up to 4 cm tall, which it did.

-

Also tested the feasibility of the tiller mechanism alongside using the handrail attached to the wheel (like normal wheelchairs) to see which is easier and less cumbersome. Results were positive for the tiller mechanism as they provided the user with better leverage to travel long distances.

Final Renders

The rear caster wheels would be at least 10" inches in diameter, and they will facilitate in the follow up directional steering of the wheelchair